Intelligente, dynamische, fracht- und mengengeregelte SBR-Technologie

Einsatzgebiete | Anwendung

- Kommunale Abwasserbehandlung im Misch- und Trennsystem für Ausbaugrößen von 500 bis 300.000 EW

- Industrielle Abwasserbehandlung

- Besonders bei industrieller Abwasserbehandlung kombiniert mit MAP-Fällung sowie anaerober Vorbehandlung

- Kombination mit wks-Dosiertechnik möglich

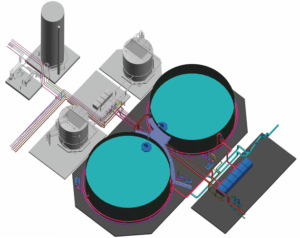

- In Anpassung an Anlagengröße 1- bis 4-strassig, wahlweise in Kombination mit Zulauf-/Ablaufspeicher

Produktbeschreibung

Das SBR-Verfahren ist eine Form des Belebtschlammverfahrens. Die räumlich getrennten Funktionskomponenten einer konventionellen Belebungsanlage werden beim SBR-Verfahren in einem Becken zeitlich getrennt realisiert. Während der Reaktionsphase erfolgt die Abwasserreinigung. In der nachfolgenden Sedimentier- und Dekantierphase erfolgt die Trennung des Belebtschlammes vom gereinigten Abwasser. In Abhängigkeit vom zu behandelnden Abwasser, wird die Belüftung durch feinblasige Druckbelüftung oder Ejektorbelüftung realisiert. Die Behälterumwälzung erfolgt wahlweise durch Impulsbelüftung, Horizontalrührwerke, Ejektoren oder mittels am Klarwasserdekanter montierten Vertikalrührwerk. Je nach Gesamtkonfiguration ist eine schubweise Beschickung zur Verbesserung der Schlammabsetzeigenschaften sowie der biologischen Phosphoreliminierung möglich.

Innovativer Kernpunkt der wks-SBR-Technologie ist die intelligente, dynamische und frachtabhängige Regelung der Prozessphasen sowie das technische System mit trübungsgeregeltem Klarwasserabzug, wasserspiegelabhängigen Vertikalrührwerk und automatischem Schwimmschlammabzug.

Der Klarwasserabzug fährt der Phasengrenzschicht Klarwasser/Belebtschlamm hinterher, damit wird die Sedimentier- und Dekantierphase auf ein Minimum begrenzt.

Konstruktionsmerkmale

- Ausrüstungssystem HydroSys mit:

- Vertikalrührwerk AW-HydroMix

- Klarwasserabzug AW-HydroDek

- Optional Klarwasserabzug AW-HydroKlar PLUS

- Schwimmschlammabzug AW-ASSS

- Automatisierungstechnik inkl. Regelbaustein RBS-SBR zur Prozessoptimierung

- Energieoptimiertes Belüftungssystem

Vorteile

- Durch Einsatz des Regelsystems RBS-SBR arbeitet die Anlage jederzeit im verfahrenstechnisch und ökonomisch optimalem Betriebspunkt

- Weitestgehende Stickstoffelimination bei betriebskostenoptimiertem Energieeinsatz

- Weitestgehende biologische Phosphorelimination

- Verhinderung einer ungewollten Phosphorrücklösung zum Ende der Reaktionsphase

- Trübungsgeregelter, flächiger und laminarer Klarwasserabzug

- Genau abgestimmte Funktionskennwerte der Komponenten für optimalen Verfahrensablauf zur Sicherung der vorgeschriebenen Ablaufwerte

- Verminderung der Energiekosten