Ökoeffektives Phosphorrecycling von phosphathaltigem Abwasser zur kostengünstigen Nutzung des Nährstoffes in der Landwirtschaft

Einsatzgebiete | Anwendung

- Bei phosphathaltigem Abwasser (PO4-P > 70 mg/l, PO4-P > 100 kg/d)

- In Kombination mit anaerober Vorbehandlung sehr effektiv

- Wahlweise Batch- oder Durchlaufbetrieb

- Je nach Anforderung an die MAP Qualität verschiedene Möglichkeiten der Aufbereitung des abgetrennten MAP möglich

Produktbeschreibung

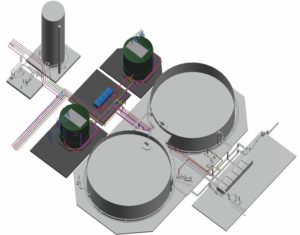

Die Bildung von Magnesium-Ammonium-Phosphat Kristallen („MAP“, Struvit) wird mit der pH-Einstellung (pH > 8,1), der Dosierung von Magnesiumhydroxid (Mg(OH)2) sowie bei Bedarf der Anpassung der Ammonium-Konzentration (NH4-N) erreicht. Die Behälterumwälzung erfolgt durch eine mittelblasige Belüftung und bewirkt eine intensive Chemikalieneinmischung sowie eine Verlängerung der Kontaktzeit der MAP-Kristalle.

Zum Rückhalt der MAP-Kristalle wird beim Durchlaufverfahren ein Parallelplattenabscheider am Behälterüberlauf eingesetzt. Beim Batch-Verfahren erfolgt der Rückhalt durch Schwerkraftsedimentation. Die bedarfsorientierte Ammonium-Dosierung wird durch Ermittlung der Ammonium-Konzentration mittels ionenselektiver Messung erzielt.

Die notwendige Magnesium-Dosierung wird durch Messung der Phosphat-Konzentration bestimmt. Für den zyklischen MAP-Abzug werden Verdrängerpumpen eingesetzt.

Die MAP-Entwässerung erfolgt durch eine Schneckenpresse, wahlweise in Kombination mit einer MAP-Wäsche zur Verbesserung der MAP-Qualität (Verringerung des oTS). Mit Hilfe der Trübwasserrückführung wird eine Optimierung der MAP-Kristallisierung erzielt. Durch den Einsatz des Regelbausteines RBS-MAP ist gewährleistet, dass ein optimaler Wirkungsgrad der Phosphat-Elimination bei geringstmöglichen Betriebskosten erreicht wird.

Konstruktionsmerkmale

MAP-Set bestehend aus:

- Verfahrensrelevanter Ausrüstung des Reaktionsbehälters (Belüftung, Zulauf- und Ablaufsystem, MAP-Abzug, MAP-Entwässerung)

- Regelbaustein RBS-MAP zur Prozessoptimierung

Vorteile

- Ökoeffektives Phosphorrecycling

- Wirtschaftlicher Betriebsmitteleinsatz durch Regelbaustein zur Prozessoptimierung

- Verringerung des Überschussschlammanfalls einer nachgeschalteten aeroben Reinigungsstufe (verringerte Fällschlammmenge)

- Erhöhung des oTS einer nachgeschalteten aeroben Reinigungsstufe (deutlich reduzierter Fällschlamm)

- Erhöhung der Betriebssicherheit einer nachgeschalteten aeroben Reinigungsstufe (Erhöhung des Schlammalters)

- Verringerte Energiekosten einer nachgeschalteten aeroben Reinigungsstufe (Einbindung von Ammonium in Struvit)

- Durch Strippung von Kohlendioxid pH-Anhebung ohne Chemikaliendosierung

- Vermarktung des abgetrennten MAP