Klarwasserabzugsvorrichtung für große Ablaufmengen bis 1.500 m³/h mit optimaler Prozesseinbindung und trübungsabhängiger Regelung des Klarwasserabflusses

Einsatzgebiete | Anwendung

- SBR-Kläranlagen

- Teichkläranlagen

- Industriekläranlagen

- Wasserversorgungsanlagen

Produktbeschreibung

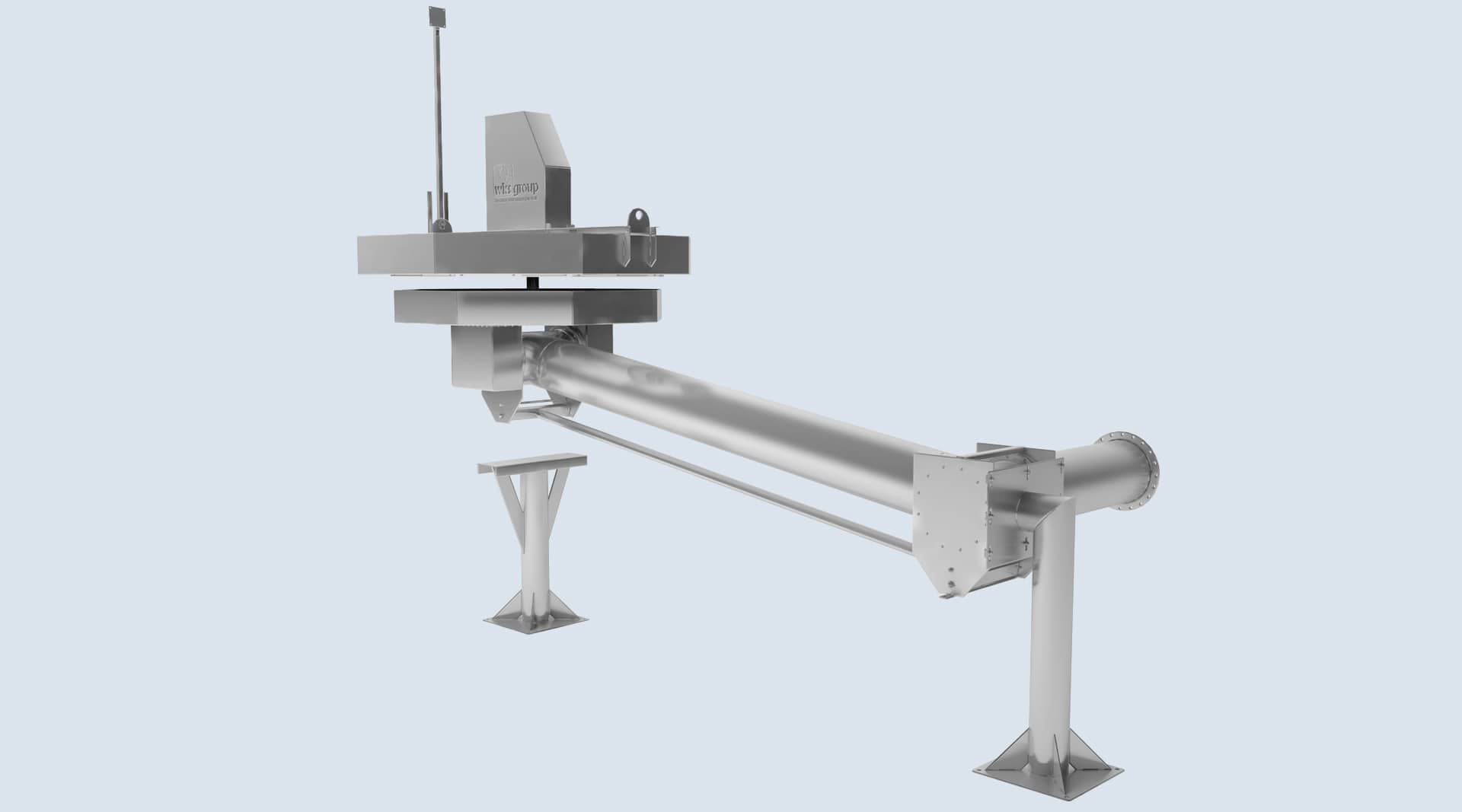

Die Aufgabe der Klarwasserabzugsvorrichtung bei der SBR-Technologie ist es, nach ausreichender Sedimentation des Belebtschlammes die Klarwasserphase abzutrennen, ohne dabei in unzulässiger Menge Belebt- und Schwimmschlammteile aufzunehmen. Die neuartige Konstruktionslösung gewährleistet diese Anforderung in hohem Maße. Das System besteht aus einem Schwimmkörper kombiniert mit einem unter Wasser liegenden Abzugstrichter. Nach der Freigabe durch das Zeitregime bzw. die Trübungsmessung wird der Abzugstrichter abgesenkt und Klarwasser über das bewegliche Ablaufrohr abgezogen. Durch die schwimmende Konstruktion folgt die Ablaufvorrichtung energielos dem Wasserstand.

Mit dem bewährten wks-Regelsystem nach Ablaufmenge und Trübung erfolgt der Klarwasserabzug bereits während der Sedimentationsphase und verkürzt so die Prozesszeit. Nach Ablauf der Abzugszeit bzw. erhöhter Trübungsmessung schließt sich der Ablauf wieder vollautomatisch und ein neuer SBR-Zyklus kann beginnen.

Konstruktionsmerkmale

- Automatische Anpassung an steigenden oder sinkenden Wasserstand durch Drehgelenkkonstruktion

- Homogener, flächig horizontaler und turbulenzarmer Klarwasserabzug

- Klarwasserabzug unterhalb des Wasserspiegels in Kombination mit Tauchwand verhindert Ansaugen von Schwimmschlamm

- Vollständig geschlossenes System während Reaktionsphasen

- Erfassung der Ablaufmengen ohne zusätzliche Ablaufmessung

- Dynamische, trübungsabhängige Regelung, dadurch Anpassung von Sedimentier- und Abzugsphase an tatsächliche Schlammabsetzeigenschaften

- Statische Stütze zur Sicherung des Mindestwasserspiegels

- Baugrößen verfügbar für Ablaufmengen von 250 bis 1.500 m³/h

Vorteile

- Unsinkbare Konstruktion, wasserstandsgeführt für Austauschvolumen bis 50%

- Anordnung der Einlauföffnung verhindert Schwimmschlammabzug

- Optimaler Prozessablauf bei regelungstechnischer Einbeziehung des Abwasserzustandes im Becken und Einbindung ins Prozessleitsystem, damit verkürzte Prozesszeit

- Erhöhung der Prozesseffizienz und damit Verringerung der Kosten

- Bus- und Ethernetanbindung

- Gute Zugänglichkeit für Wartung durch begehbare Vorrichtung

- Erhebliche Verringerung des Speichervolumens bei Neuauslegungen

- Geeignet für Anlagenerweiterung als Nachrüstung