Prozessleitsysteme zur Erfassung/Auswertung verfahrenstechnischer Daten von Anlagen

Einsatzgebiete | Anwendung

- Trink- , Regen- und Abwasseranlagen

- Biogas- und Industrieanlagen

- Wärmeversorgung

Produktbeschreibung

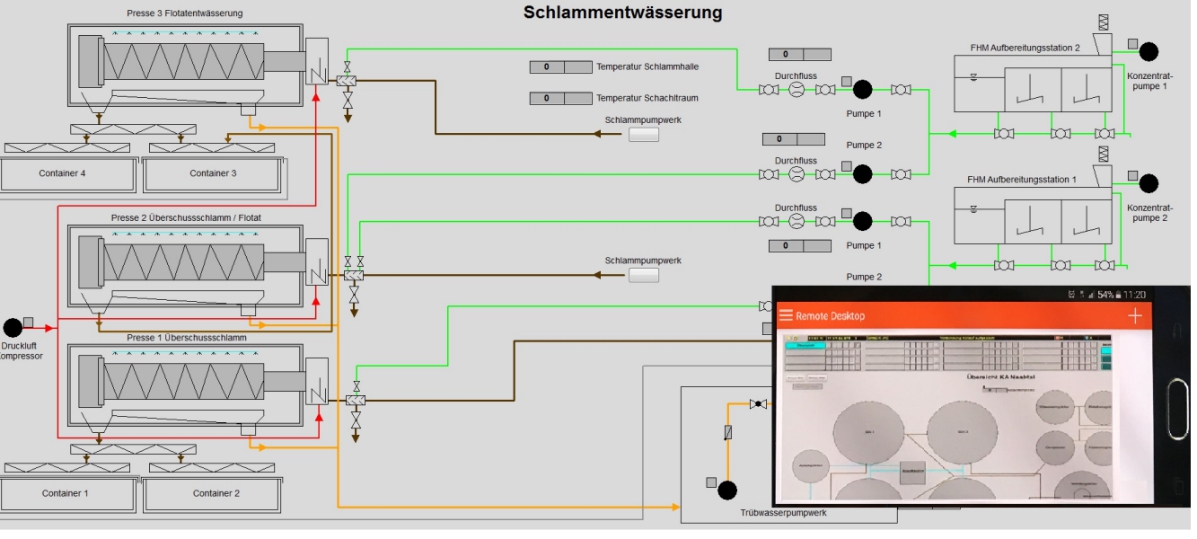

Die Prozessleitsysteme WinCC & PCS7 der Firma Siemens dienen der Erfassung,Visualisierung, Weiterverarbeitung und Auswertung von Prozessdaten. Es handelt sich um frei skalierbare Prozessvisualisierungssysteme mit leistungsfähigen Funktionen zur Überwachung von automatisierten Prozessen. WinCC & PCS7 bieten komplette SCADA-Funktionalität unter Windows für alle Branchen – von Einplatz- bis hin zu verteilten Mehrplatzsystemen mit redundanten Servern und standortübergreifenden Lösungen mit Web-Clients.

Unterstützte Protokolle/Systeme:

- S7-Ethernet, S7-MPI, S7-Profinet, SINAUT

- OPC Classic, OPC UA

- S5, 3964R

Eigenschaften

- Frei skalierbar

- Universell einsetzbar

- Datenbanksystem: Microsoft SQL

- Alarmierung über ISDN, GSM, Internet, VOIP

- iPhone-App für Bereitschaftsdienst

- Schnittstelle zu Microsoft Excel

- Auswertmöglichkeiten von Ganglinien / Trends

- Vektororientierte Visualisierung

- WebNavigator für Bedienung über Internet

- Anbindung an Datenbanken und IT-Systeme

- Erweiterbar über Optionen und Add-ons

- Unterstützt durch einen .NET Container die Integration eigener technologiespezifischer XAML und .NET Controls

Vorteile

- Individuell einsetzbares System

- Intuitiv bedienbares System

- Hochverfügbar

- Unterstützt Redundanz

Datenblätter

Datenblatt WINCC & PCS7Ansprechpartner

Axel Marx

Geschäftsführer wks Automation GmbH

a.marx@wksgroup.de