Fremdenergiefreier mobiler Kanalspülwagen für ressourceneffiziente Abflussreinigung von Mittel- und Großprofilen

Einsatzgebiete | Anwendung

- Kanaldimensionen ≥ 1.500 mm

- Lange Transportkanäle

- Lange Kanalstauräume

- Industrielle Einrichtungen

Produktbeschreibung

Die derzeit am häufigsten genutzte Reinigungstechnologie bei Abwasserkanälen ist die kombinierte Hochdruckspülung mit Absaugung des Schlamm-Wasser-Gemisches. Dieses Verfahren ist insbesondere bei großen Kanal-Nennweiten mit hohen Kosten, einer starken Umweltbelastung und einer erheblichen Gesundheitsgefährdung des Bedienpersonals verbunden.

Der neu entwickelte Kanalspülwagen zeichnet sich im Gegensatz dazu durch eine fremdenergielose, emmissionsfreie und gesundheitsfreundliche Arbeitsweise aus.

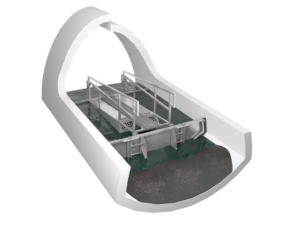

Der RW-S-KSW wird zum Einsatz gebracht, um lange Kanäle mit geringem Gefälle automatisch und fremdenergiefrei von Ablagerungen zu befreien (Abtransport von mineralischen und organischen Ablagerungen). Er wird dazu in den Misch- bzw. Abwasserkanal eingesetzt.

Das strömende Wasser schiebt durch Aufstau den Wagen, gebremst auf ca. 1–10 cm/min (abhängig von der zu transportierenden Menge), vorwärts. Unter Nutzung der Energie von Ober- zu Unterwasser, nimmt eine fest definierte Spülwelle vor dem Stauschild, die Ablagerungen vor dem Wagen auf und transportiert diese kanalabwärts. Die Ablagerungen werden über weite Strecken bis zu einer günstigen Entnahmemöglichkeit des Raumgutes sowie des Gerätes transportiert. Da diese Reinigungsmethode nach dem Einsetzen völlig fremdenergie- und ressourcenlos funktioniert, kann der Wagen längere Zeit im Kanal verweilen. Dabei werden die Ablagerungen langsam und effektiv bis zum Sandfang geschoben, ohne dabei den Abflussbetrieb zur Kläranlage oder den oberirdischen Verkehr zu behindern.

Die Entwicklung wurde gefördert durch die Deutsche Bundesstiftung Umwelt.

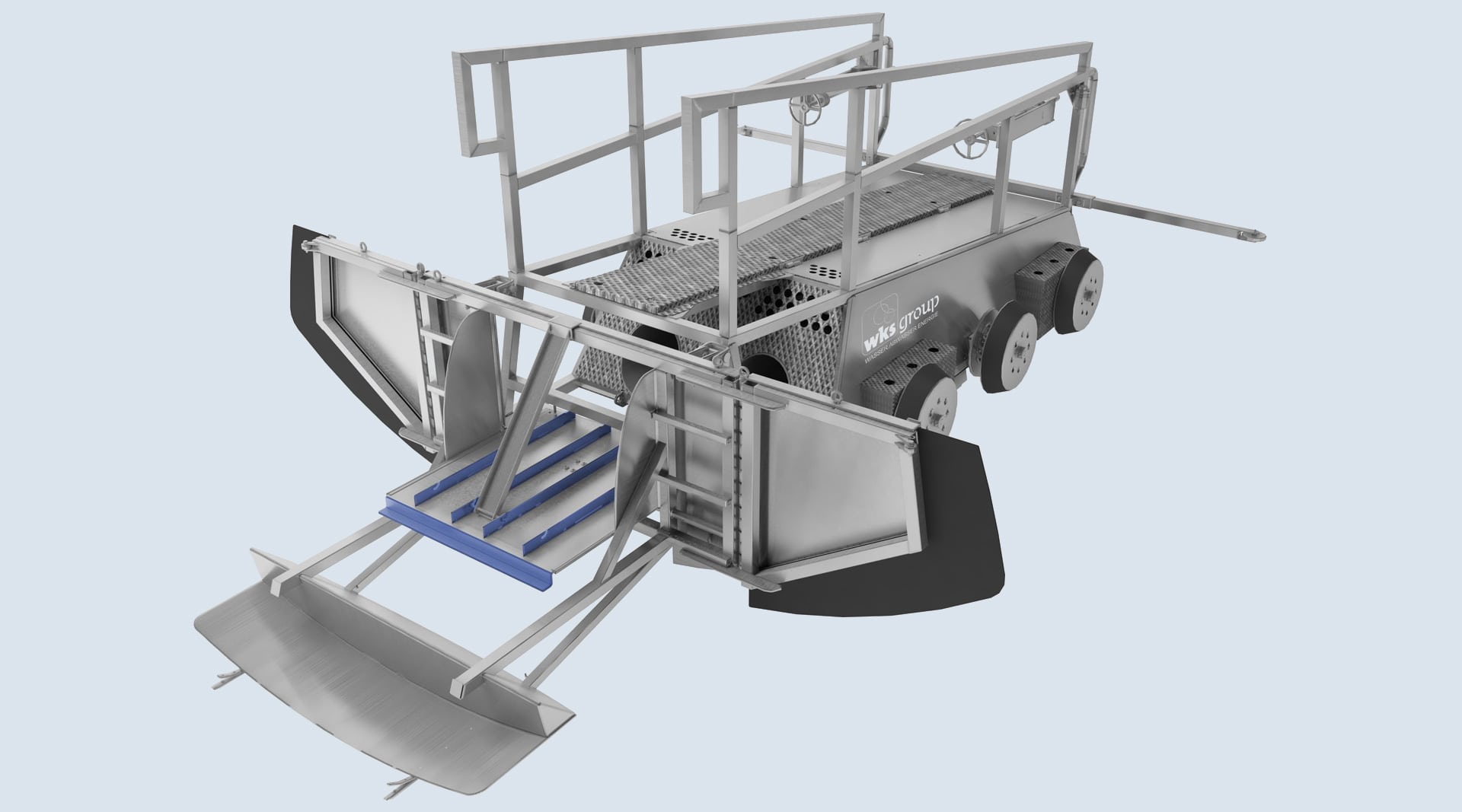

Konstruktionsmerkmale

- Schwenkbare Seitenklappen zum Anpassen an verschiedene Rohrquerschnitte

- Automatische, an Wasserstand angepasste regelnde Entlastungsklappe

- Strömungsgünstige Konstruktion zur Vermeidung des Verzopfungsrisikos

- Hydraulische Negativ-Bremsen zur Regulierung der Reinigungsgeschwindigkeit

- Modulierbarer Aufbau zum Einbringen der Komponenten in den Kanal

- Werkstoff- und funktionsoptimierte Konstruktionen bestehen aus Edelstahl

Vorteile

- 100 % umweltfreundliches Kanalreinigungsverfahren (kein Energie- und Frischwasserverbrauch während der Reinigung)

- Kostengünstige Kanalberäumung durch geringe Investitions- und Betriebskosten: 5–10-mal kostengünstiger als Hochdruckreinigung

- Große Reinigungslängen bedienbar und reduzierter Einsatz von Saugfahrzeugen

- Wirkungslänge ausschließlich durch örtlichen Gegebenheiten des Kanalnetzes bedingt

- Automatische, fremdenergiefreie Kanalräumung

- Hohe Betriebssicherheit durch unbemannten Einsatz

- Im Vergleich zu Hochdruck-Verfahren keine Gefahren der Kanalbeschädigung

- Keine Verkehrsbehinderung

- Verbesserung der Arbeitssicherheit und damit stark reduzierte Gesundheits- und Unfallgefahren